caramel color

Hengtai®Caramel Color:A professional caramel color manufacturing factory with over 20 years of experience,

What is Caramel Color?

Definition

Caramel color is also known as “the color of soy sauce or syrup”. It is a colloidal polymer made by carbohydrates through high-temperature polymerization with reactants or not.

What is Caramel Color made from?

Carbohydrates: fructose, fructose syrup, glucose and its mother liquor, xylose and its liquor, sucrose, maltose, molasses, starch hydrolysate, etc.

Reactants: ammonium based compounds and sulfites.

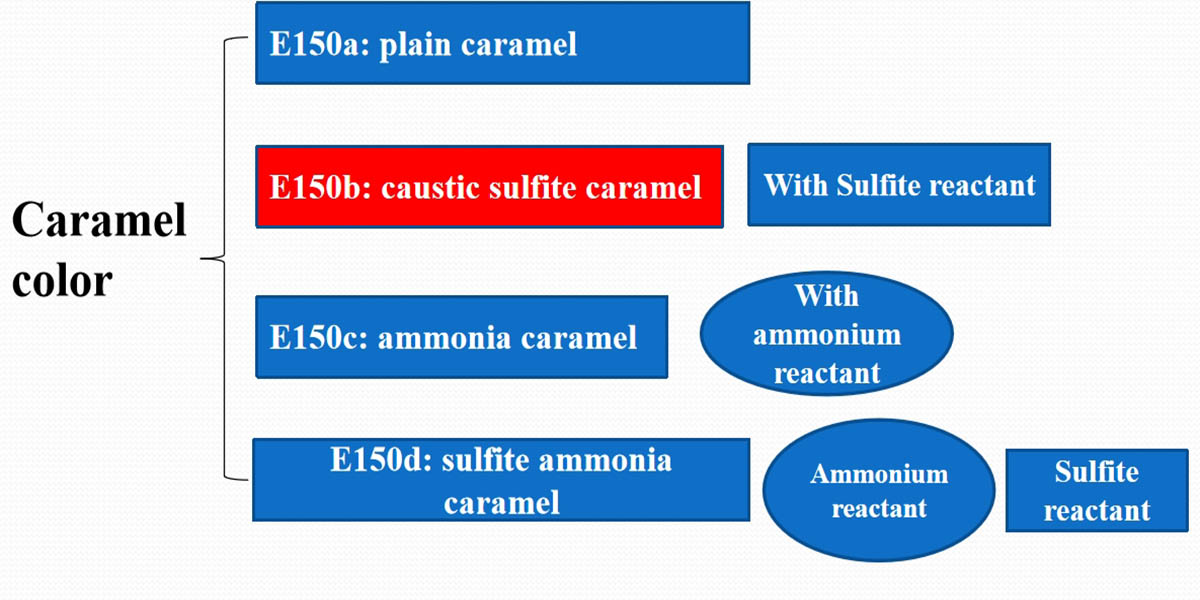

Categories of Caramel Color

National Implementation Standards of caramel color: GB 1886.64-2015

1. Class I: E150a

No ammonium or sulfite reactants. Also called caustic or plain caramel color.

2. Class II: E150b

With Sulfite reactant, but no ammonium. Also called caustic sulfite caramel. With sulfite compounds (sulfurous acid, potassium sulfite, potassium bisulfite, sodium sulfite and sodium bisulfite); no ammonium compounds are used.

3. Class III: E150c

With ammonium reactant, but no sulfite. Also called ammonia caramel. In the presence of ammonium compounds (ammonium hydroxide, ammonium carbonate, ammonium hydrogen carbonate and ammonium phosphate); no sulfite compounds are used.

4. Class IV: E150d

With both sulfite and ammonia reactants. Also called sulfite ammonia caramel. In the presence of both sulfite and ammonium compounds.

Manufacturing Techniques of Caramel Color

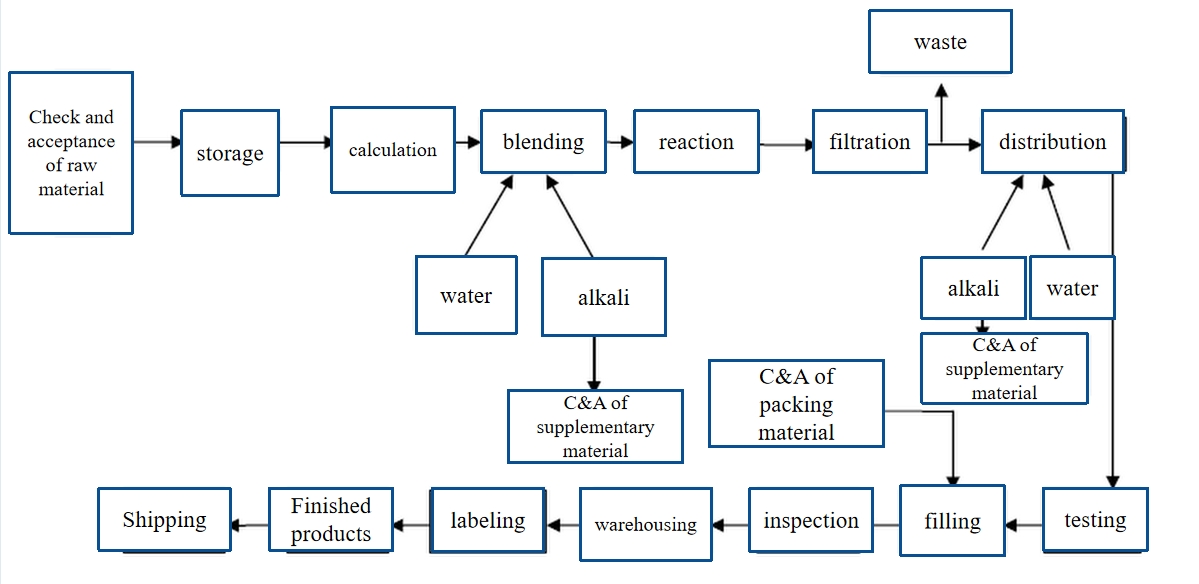

Manufacturing Techniques of Caramel Color— Plain Caramel

- Plain Caramel (150a): obtained under the temperature of 160℃ with glucose syrup (DE≥90%), no ammonium or sulfite compounds used.

Manufacturing Techniques of Caramel Color—

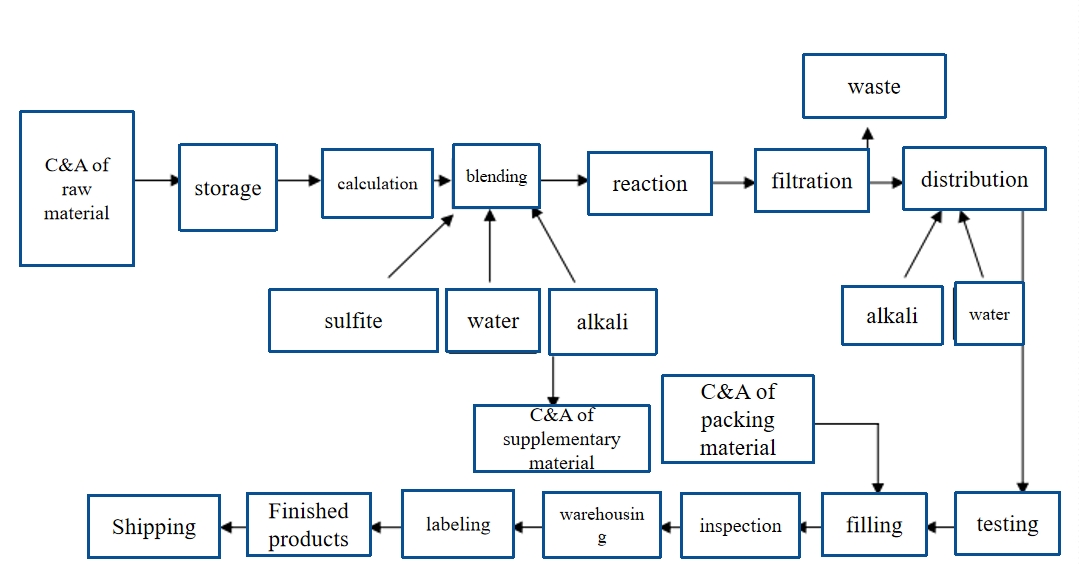

Caustic Sulfite Caramel

- Caustic Sulfite Caramel (150b): similar to Plain Caramel, but with sulfite as the reactant obligatorily. This type requires high consumption of reactant, and commonly uses glucose and sodium sulfite in controlled heat treatment. Its application range is narrow, and is only used in some special foods or medicines.

Manufacturing Techniques of Caramel Color—

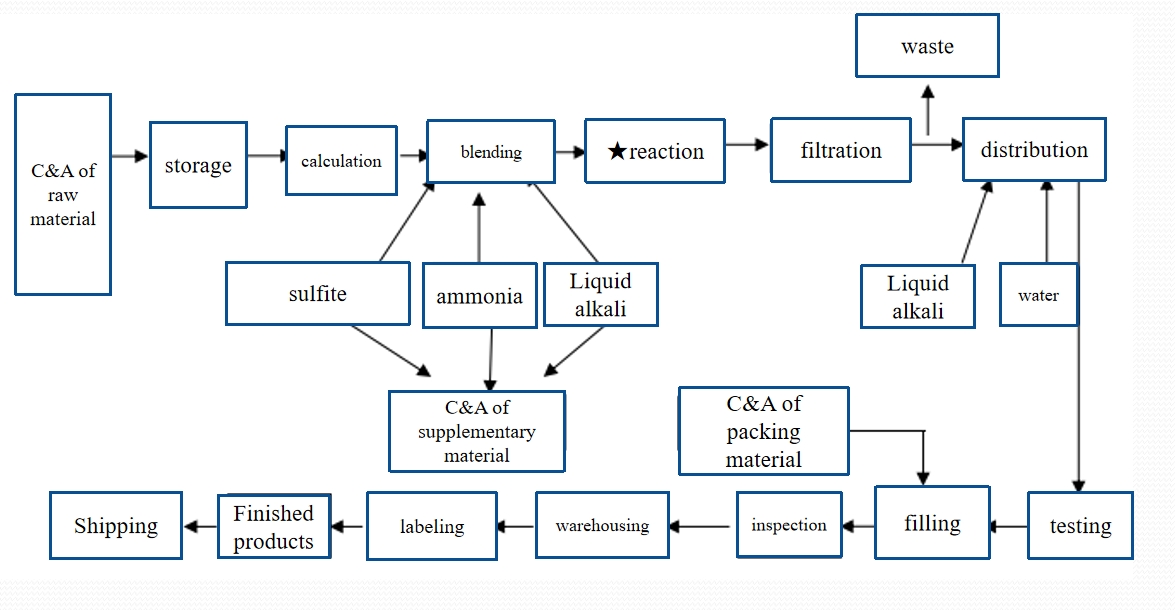

Sulfite Ammonia Caramel

- Sulfite Ammonia Caramel (150d): obtained under acidic condition, in the presence of both sulfite and ammonium compounds with ammonium sulfite as the reactant and glucose or sucrose as the material.

Main Applications of Caramel Color

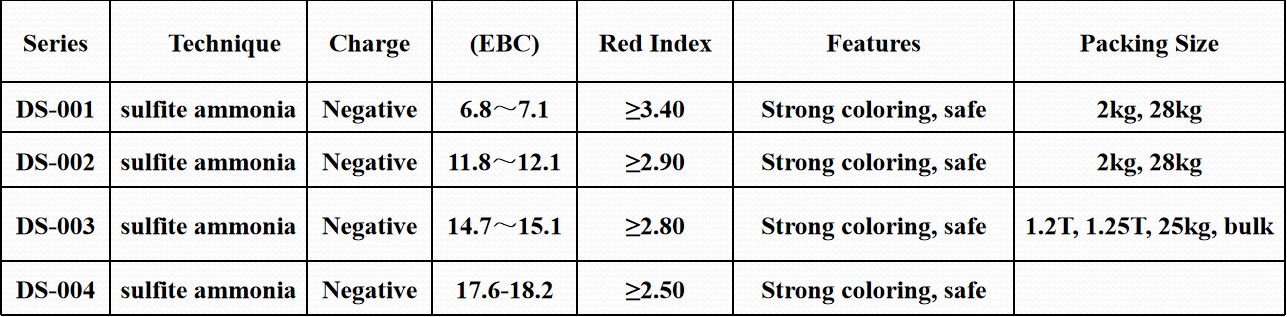

Double strength caramel color(Sulfite Ammonia Caramel)

Main applications: carbonate beverages, juice, tea beverages, wines, ice creams, puddings, bakery products, and so on. The PI is lower than all carbonated beverages’ pH, which avoids flocculent precipitation when added. The caramel is well soluble, acid-resisting, alcohol-tolerant, and stable in the quality.

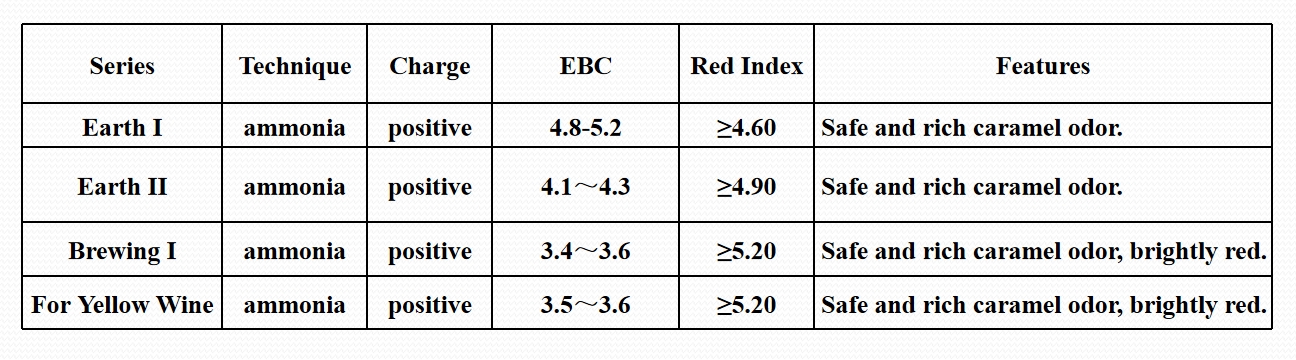

Ammonia Caramel

Main applications: vinegar (1.0‰), biscuits, yellow wine (30‰), flavored syrups, sauce and sauce products, etc.

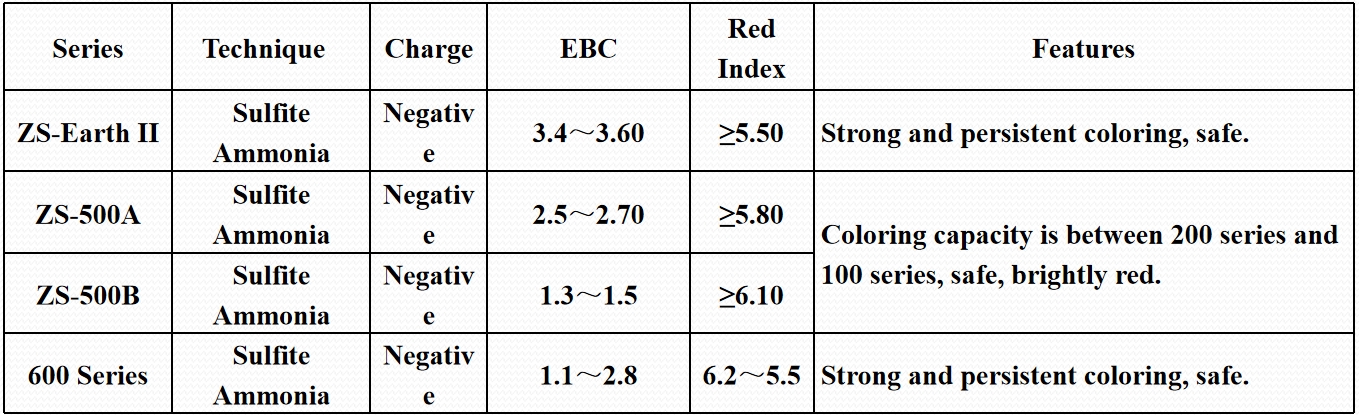

Sulfite Ammonia Caramel

Main applications: soy sauces, oat meals (2.5‰), flour pastes (2.5‰), fruit powders (2.5‰), biscuits, cooking wines (10‰), compound seasonings (50‰), tea beverages (10‰), coffee beverages (0.1‰), and so on.

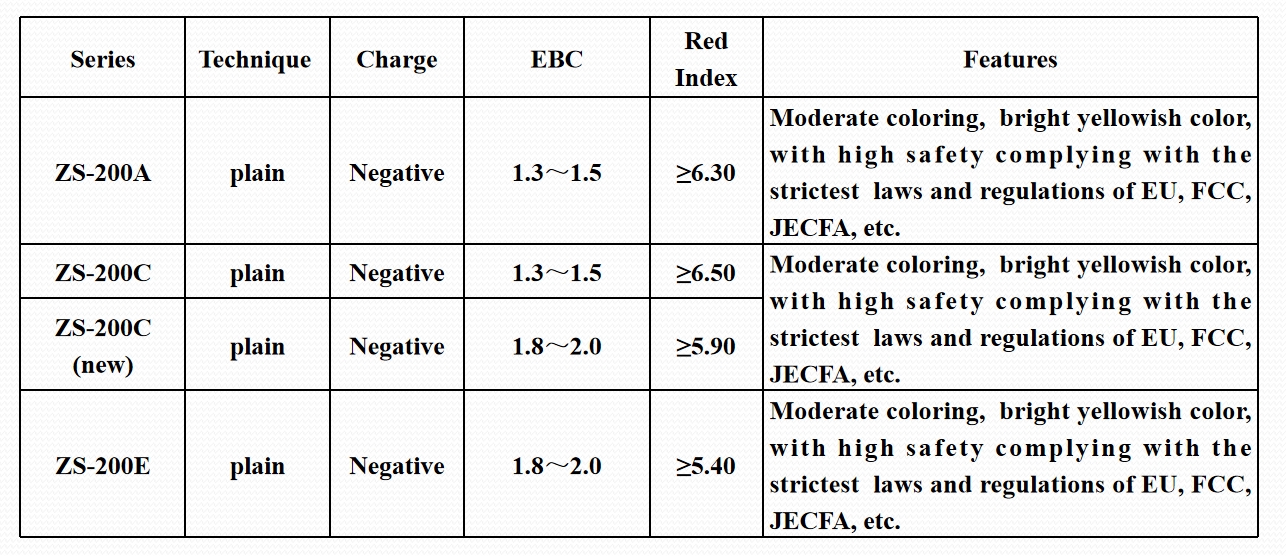

Plain Caramel

Main applications: high-end soy sauces, vinegars, flour pastes, fruit powders, biscuits, compound seasonings, fruit & vegetable juice/pulp, baking fillings and coating materials, etc.

Get in Touch With Us

Let’s Connect

0086-028-38260750

Address

Minjiadu,Chengnan Dongpo District,Meishan city,Sichuan,620000,China.